Shared Knowledge

"BMW Z3 - No Air Conditioning (AC)"

18 May 2016

Summary: Don't rush off to dealer or repair shop without first checking various yourself.

Background:

Z3: 1997, 2.8L, 61,000 miles.

First use after winter, spring, no cold air with AC button pushed "on".

BMW Z3 air conditioning (AC) System Operating Overview (Click Here)

Steps to Diagnosis Problem:

Fuses

Open hood and find fuse box on driver's side (American) and remove cover.

Use map on inside of removed cover to find all fuses related to AC.

Remove each one at a time and visually inspect. If burnt through in middle or at ends, replace.

If you have a voltmeter with continuity checker, check each AC fuse is, in fact, good.

Replace any bad fuse with correct amperage fuse and test AC.

If fuses are good and their removal and reinsertion do not fix problem, look at relays in fuse box. And yes, overtime, contacts begin to corrode or otherwise not carry 12volt direct current as they should. More of a problem with older British cars but also on older models of any car.

Relays

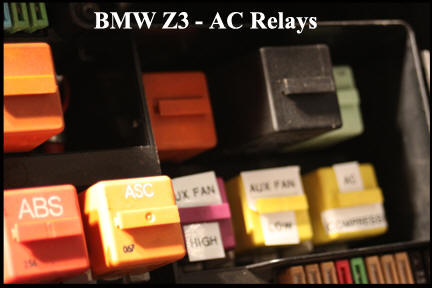

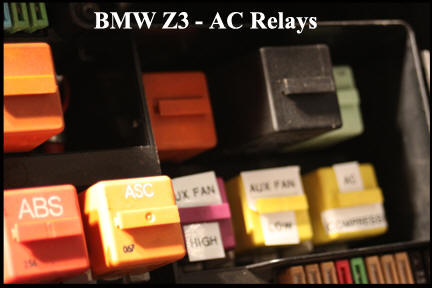

With cover off fuse/relay box, locate the large ASC relay.

The 3 smaller relays to the right of the ASC relay are all involved with AC.

The small relay next to the one marked ASC is the auxiliary fan, high speed relay.

The next relay, although marked aux fan is actually the compressor relay.

The third relay is the actual auxiliary fan relay.

NOTE: the compressor fan and the aux fan relays are the same model number and can be interchanged. This is reason they are switched in image above.

With ignition key out of car, remove each one of the 3 relays. Inspect for visual damage.

Reinstall all 3 relays and test AC.

If no AC, remove the middle relay and swap it for the 3rd relay.

Test AC.

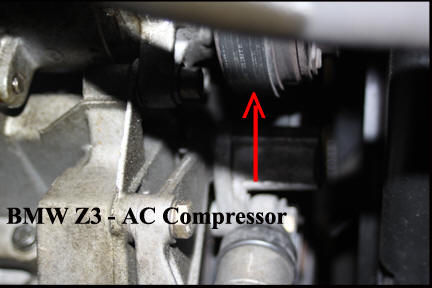

Compressor fan belt: First of all, jack up Z3 on left side, as facing the front of the car. Make sure you pull the emergency brake.

Jack the Z3 up enough so you can lay on floor and look up and find compressor unit.

Does compressor have fan belt around it? Is belt tight via the belt tensioner you should see??

If compressor belt missing or not tight, replace belt and/or/ tensioner.

Compressor Clutch Engaging?

The belt around the crank shaft turns a pulley on the front of the AC compressor. If belt is there, will see belt going around.

Now look carefully and the end, center of the compressor unit. Is the center going around?

If center is going around or compressor has been engaged, most likely unit is low on coolant.

If the center of compressor is not turning, magnetic clutch has not engaged.

Magentic Clutch on Compressor Not Engaging:

With buttons, controls, relays, fans, pressure sensors, any of these could be causing a problem BUT most likely cause is that the amount of 134a in the system is low or below the pressure threshold for the sensor in the dryer to allow the system to run.

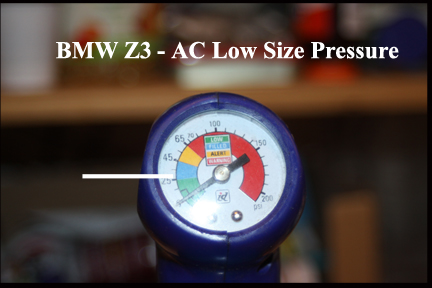

SOooooooooo....go to an auto parts store and buy a large can of 134a with an included pressure gauge.

Also buy a can of sealant with it's special hose and tap.

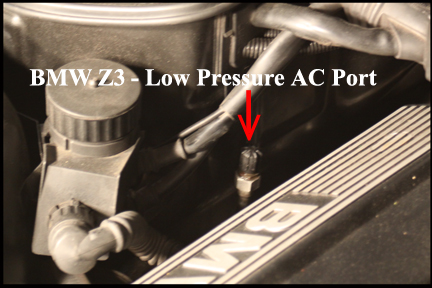

There are two (2) "Freon" service ports: a low pressure port and a high pressure port. The high pressure port is close to the radiator while the low pressure port is close to the firewall.

Both ports have plastic caps on them. Only the low pressure port will accept the can of sealant or 134a.

Take the can of 134a and screw on the gauge and hose. Do not over tighten the gauge and hose to the can. The metal of the can is soft and you can easily strip newly created threads on can.

With gauge on 134a can, remove plastic cap on low pressure port. It might be tight and require pliers to loosen.

Now start Z3, push in AC button, set temp to coldest setting and turn cabin blower to high.

To connect can of 134a to low pressure port, pull back on hose connector and then push it straight down over port. It should latch into place.

Looking at gauge, if pressure is not reading at all, remove hose from port and try to seat it again.

If gauge shows no pressure at all, all 134a in system has leaked out for some reason and although you can try your can of sealant, doubt it will solve the problem and best to take to AC repair shop for them to find leak and correctly clean all tubing, dryer, and fill with 134a.

If you have some pressure in system but not showing in the blue area on the gauge, follow the directions on the can of 134a and press the trigger allowing gas to flow into the AC system. Do not be surprised if suddenly you hear the compressor clutch engage and the auxiliary fan start up.

Add some more 134a to system and then stop.

If pressure was low, means there is a leak in the system and best try to seal it with your can of sealant.

Remove 134a hose from low pressure port and connect can of sealant. Follow directions on sealant can.

Once all sealant in system, let system idle for a good 15 minutes to properly circulate the sealant.

As can be inferred from above, there are both mechanical and electric involved in the AC system.

First thing to do is to start the Z3, turn temperature control to coldest setting and push "in" the AC button in.

Now get out of car, lift hood and see if the auxiliary fan is running.

If the auxiliary fan is not running, shut down Z3 and go to the fuse box. On the inside of the lid will be defined all fuses related to the compressor and fans. Pull each fuse one at a time, using the provided fuse puller and check using an ohm meter or continuity checker.

If any fuse is blown replace with same amperage.

Next look at the fuse box relays.

Once you have swapped relays, start Z3 and